History of Pollution Control at the Sullivan Mine and Concentrator, Kimberley, B.C.

By Leslie McDonald, RP Bio (Senior Impact Assessment Biologist, BC Environmental Protection, Cranbrook Office 1979 – 2007).

Much has been written and done on the socio-economic history of the Cominco Sullivan Mine and Concentrator operations in Kimberly, BC. The mine was discovered in 1892; the last ore was shipped out in 2001. Today the Sullivan Mine and Railway Historical Society operates a small gauge train loop around the old mine property that includes an underground portion into part of the old mine and has done an excellent and informative job of preserving Kimberley’s mining heritage, celebrating the mine’s importance to the social and economic fabric of the city, region and the province.

Sullivan Mine and Concentrator

A Google search of the Sullivan Mine and Concentrator will turn up somewhat less information about the environmental damage done to Mark Creek and the St. Mary River, and the eventual clean-up work that eventually eliminated most of the impacts. Using the right keywords, one will find some publications describing the extensive research and investment undertaken by Cominco, and its successor company, Teck, to treat the waste, but next to nothing will be found of the role of government regulations and the work done by staff of the Ministry of Environment to assess this damage and to pressure Cominco for not taking action. This is not to take anything away from the massive and expensive efforts by the company and its employees, but the story is incomplete without acknowledging the work of the Ministry of Environment in this success story. Though at times an adversarial relationship, in retrospect, this pollution reduction was in a real sense a partnership between industry and government.

The history of environmental contamination and the ongoing mitigation and eventual clean-up at Sullivan is complex and extends over most of the 20th century when societies and governments the world over were slowly forced to come to terms with the environmental damage done by industry, all the while enjoying the considerable associated economic benefits. This essay is not intended as an exhaustive treatment of the subject but rather seeks to provide some understanding of the process and the ultimate successful outcome, using Cominco’s Sullivan Mine (1909 – 2001) as a case study.

The huge ore body that was Sullivan included the sulphides of lead (galena), zinc (sphalerite) and iron (pyrrhotite, pyrite and limonite), which, when mined and exposed to air, produced sulphuric acid rock drainage. The acid dissolved the metals (lead, zinc, and cadmium), which, along with the acid itself, were toxic to aquatic life. An ore concentrator was built in 1923 to separate the valuable ore from the waste rock. Excess water from the ore processing and precipitation filtering through the waste rock dumps was acidic and high in toxic metals, and for decades, this contaminated water was simply discharged into nearby waterways.

Government Regulation

The history of pollution regulation in British Columbia dates to its establishment as a British colony in 1858 and the adoption of British Common Law protection of individual property rights. Pollution from growing settlements led to the Colony’s first Health Ordinance in 1869 and the establishment of local Health Boards to deal with all matters relating to:

“Drains, sewers, privies, pigsties, slaughterhouses, unwholesome food, diseased cattle, noxious or offensive trades or businesses, epidemic, endemic or contagious disease or disorders, and for the summary abatement of any nuisance or injury to public health likely to arise therefrom.”

This authority was eventually captured in the provinces’ first Health Act in 1892, following B.C.’s entry into the new Dominion of Canada in 1872. The Health Act was modified and strengthened over the years, but, in general, through the first half of the 20th Century, pollution regulation in B.C. continued to focus on sewage sanitation and related health concerns.

In 1956, the BC legislature passed the first Pollution Control Act, which prohibited the discharge of waste except under permit and established the first Pollution Control Board to set standards for effluent that could be discharged. The legislature was forced into passing this act because of a dispute between the cities of Vancouver and Richmond when the former proposed expropriating land in the latter to construct the Iona Sewage Treatment Plant, which would discharge treated sewage from Vancouver to the north arm of the Fraser River. For this reason, the act and actions of the Pollution Control Board were restricted to wastes within municipal boundaries, which generally meant sewage. In 1965, the responsibility for pollution control was moved from Municipal Affairs to the Department of Lands, Forests, and Water Resources, and in 1967, the Act was amended to include industrial waste.

With the 1967 amendment of the Pollution Control Act came the establishment of an agency, the Pollution Control Branch, to issue and enforce permits and to conduct environmental studies to assess the severity of discharged waste. Regional offices were established across BC and staffed with engineers, technicians, and biologists.

This new version of the act included 23 sections covering a mere six pages, with one enabling regulation. Its modern-day offspring, the Environmental Management Act, comprises 179 sections and 41 associated regulations such as the Hazardous Waste and Contaminated Sites Regulations. The Act prohibited the discharge of any waste into the environment unless authorized by a permit and set a deadline of the end of 1971 for all discharges of waste to register and file applications for permits. The role of the Pollution Control Board expanded to adjudicate permit appeals. The name of this program was changed over the years from the Pollution Control Branch to the Waste Management Branch to Pollution Prevention and finally to Environmental Protection. The name changes generally followed the evolving changes in the legislation. The Pollution Control Act (1967) was replaced with the Waste Management Act (1979) and then the Environmental Management Act (2003).

The Kootenay regional office of the Pollution Control Branch was in Nelson, with Cranbrook serving as a sub-regional office responsible for the East Kootenays. In the late 1960s and early 1970s Pollution Control staff spent much of their time sampling rivers, lakes and waste discharges, gathering information on the effects of waste discharges on water, land and air quality that would be used to refine the early versions of permits. Larger more intensive studies often included science specialists from the Victoria office and one such effort was titled the Kootenay Air and Water Quality Study, a multi-year effort, that was divided into two phases and produced in several volumes summarizing industrial and municipal waste sources and their effects on the environment throughout southeastern BC. I have used this document as a major source of the following information.

Sullivan Mine Processes

The Sullivan mine was initially a surface mine, taking advantage of shallow or outcropping ore, but soon moved underground, eventually excavating 500 km of tunnels. The mine was accessed via an adit at the 3900 ft elevation, while ore was removed via rail at an adit at 3700 ft. As mining progressed deeper, accumulating groundwater had to be continuously pumped to the surface, and this, along with surface runoff and seepage through waste rock dumps, was discharged to Mark and Kimberley Creeks.

The crushed underground ore was transported by rail 6 km down valley to the concentrator, which began operation in 1923 with an initial 2,500 tons/day capacity that was soon increased to 10,000 tons/day. The resulting lead and zinc concentrates were shipped by rail to Cominco’s smelter in Trail, B.C. Contaminated wash water from the concentrating processes was collected in large tailings ponds, the siliceous and iron ponds, and overflows from these ponds were discharged to James Creek and the St. Mary River.

Though the operation’s target metals were lead, zinc, and silver, other related products were produced at Sullivan. Smaller quantities of tin concentrate were shipped directly to available markets. In 1961, pig iron production commenced at a capacity of 110,000 tons/year, and in 1966, a steel plant was constructed, producing 80,000 tons/year. These plants were closed in 1971 and 1972, respectively.

In 1953, the company began fertilizer production, using iron sulphide from the concentrator to produce sulphuric acid, then reacting this with phosphate rock from a Cominco mine in Montana and ammonia from a company plant in Calgary. The result was Elephant brand ammonium phosphate fertilizer. Iron sulphide slurry was dewatered, and the wastewater was discharged to Mark Creek via sewer 32 and then roasted to produce sulphur dioxide gas and iron oxide or calcine, which was stored in the calcine pond. The sulphuric acid was reacted with the phosphate rock (calcium fluorophosphate), which produced phosphoric acid and waste calcium sulphate (gypsum) slurry, the liquid portion containing high concentrations of fluoride and phosphorus. The phosphoric acid was then reacted with ammonia to produce ammonium phosphate fertilizer.

In the 1950s, the large quantities of gypsum waste from the fertilizer plant were stored in an impoundment on the north bank of the St. Mary River, just below the confluence with Mark Creek. With the agreement of the BC Department of Recreation and Conservation, the gypsum waste was stored in this pond for 10 months and discharged to the St. Mary River during the May and June freshet when river flows were at their annual highest. Increased fertilizer production resulted in increased gypsum waste, from 375 tons/day in 1960 to 1,800 tons/day in 1966, and discharge to the river became continuous. Ironically, before the construction of the Libby Dam on the Kootenay River in Montana in 1972, the vast quantities of phosphorus waste from this operation resulted in an increase in biological production in Kootenay Lake through the 50s, 60s and early 70s that culminated in trophy Girard rainbow trout that reached 30 pounds. However, life for fish in the St. Mary River was not as good.

Gypsum pond (1976) before reclamation in the 1980s. Mark Creek (seen entering the St. Mary River as a light brown plume) was diverted through the pond during freshet to wash the gypsum waste into the St. Mary River.

Environmental Impacts

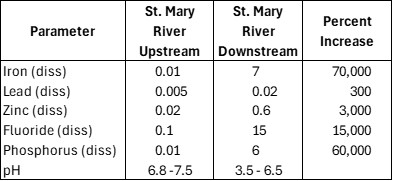

In rivers, the simplest way to gauge the impact of a waste discharge is to compare samples taken upstream with those from downstream of the point of discharge. Also, the greatest impact of a constant source of waste is when stream flows and dilution are at their annual lowest, typically March in the East Kootenays. The upstream sample site on the St. Mary River was located 1.2 river km above the Mark Creek confluence, and the downstream site was located at the Wycliffe Bridge, 8.5 river km downstream of Mark Creek. Many other sites were sampled, but these have the longest period of record. Downstream increases in metal and other contaminants were enormous, ranging from a 300 % increase in dissolved lead to a 70,000 % increase in dissolved iron.

Low river flow concentration of contaminants from Sullivan Mine and Fertilizer Plant Operations, 1970 – 1973.

Mark Creek entering the St. Mary River, early spring 1974.

St. Mary River from Wycliffe Bridge, early spring 1978.

A simple integrated method used to determine the impact of this pollution on the river was to place juvenile rainbow trout flow-through cages upstream and downstream of Mark Creek. These are known as in situ bioassays. The BC Fish and Wildlife Branch conducted the first such study in September 1965. Cages containing 18 trout were placed in the St. Mary River just above Mark Creek and another at the Wycliffe Bridge. After 20 days, all 18 were alive and in good condition in the upstream cage; downstream, all 18 were dead. Similar studies were conducted again by Fish and Wildlife in 1969 and the Pollution Control Branch in 1973 and 1974 with similar results.

Pollution Abatement 1975 – 2001

By 1970, Cominco had registered all the known sources of contamination throughout the property with the BC Pollution Control Branch, and measures began to capture and reduce discharges to surface streams. Cominco’s effluent permit, PE 189 (meaning it was the 189th such

permit issued in BC), had been amended to set realistic limits on the quantity and quality of the various effluents. In 1975 an important pollution abatement measure was the recycling of gypsum wastewater through a cooling pond for reuse in the fertilizer plant. This greatly reduced the volume of waste high in fluoride and phosphorus entering the St. Mary River.

To comply with effluent permit limit restrictions Cominco, in the mid-1970s, began research on a process to treat the acidic wastewater from waste rock seepage, plant effluent and storage pond sources. This culminated in the commissioning of the first high-density lime neutralizing plant, called the Drainage Water Treatment Plant, in September 1979. Accumulated wastewater in the large iron and calcine ponds was piped down to the plant, located on the north side of the St. Mary River, just upstream of the Kimberley sewage treatment plant. Slaked lime is mixed with the acid drainage with aeration resulting in the metals precipitating as a solid sludge. The sludge, with the aide of a flocculant, is separated from the now low metal liquid in a clarifier. Some sludge is returned to the front of the process to serve as a chemical seed, the underflow sludge from the clarifier is piped to a landfill to the south side of the river. The effluent, now with very low metal concentrations is discharged to the river via a multi-port diffuser.

In 1990, anticipating the exhausting of the economically mineable ore by 2001, Cominco began developing a Decommissioning and Closure Plan, required by the Ministry of Energy, Mines and Petroleum Resources. A key feature of this process was the establishment of the Sullivan Public Liaison Committee, chaired by the local Mines Ministry manager with participation of Ministry of Environment, local governments, concerned public and the East Kootenay Environmental Society. In 1971 the Ministry of Mines issued Cominco a reclamation permit requiring the company to revegetate as much of the property as possible during operations. Reclamation work accelerated through the 1990s up to closure of the operation in 2001 and has continued post-closure.

Drainage Water Treatment Plant (Google Earth image Sept 20, 2024). Kimberley wastewater treatment plant lagoon on right.

Drainage Water Treatment Plant sludge landfill on south side of St. Mary River (Google Earth image Sept 20, 2024).

St. Mary River 2024

A water sample taken from the St. Mary River downstream of James Creek (which is below Mark Creek) in November 2024 found 0.000116 mg/L total lead, 0.0036 mg/L total zinc, and 0.067 mg/L fluoride. These concentrations of contaminants from the mine and fertilizer operations represent a 99.4%, 99.4%, and 99.5% reduction in these contaminants since the 1970 – 1973 period. In all cases, the 2024 concentrations of these three contaminants were below the BC Guidelines for the Protection of Aquatic Life.

Soon after the commissioning of the Drainage Water Treatment Plant in 1979, fish began to return to the St. Mary River below Mark Creek. The lower river is now home to thriving populations of cutthroat trout, Bull trout, burbot, mountain whitefish, kokanee, mountain whitefish, and suckers. The river has become one of the premier fly-fishing streams in BC for cutthroat and Bull trout.

Cutthroat trout caught on the St. Mary River. Courtesy Kimberley Fly Fishing, operating guided fly fishing on the St. Mary River for over 20 years.